Many sectors are following the trend of using new materials.

In order to make use of composites or light alloys, it is necessary to understand both their behavior and their interaction with the structures in which they are used. This understanding is also useful to materials manufacturers and can impact manufacturing processes.

The Advanced Modeling of Materials and Structures program offers students a fascinating field of study and research drawing on the work of teams at Institut de Recherche Dupuy-de-Lôme (IRDL), whose applied research is carried out in close collaboration with large industrial firms.

Program strengths

A multiplicity of applications

Steel, composites and elastomers have diverse applications in the automotive, medical, naval, aerospace, defense, construction and clothing industries.

Gaining an understanding of their structure, behavior (especially during forming and annealing), aging process and reaction to damage is a necessary first step before their utilization.

Cutting-edge applied research

ENSTA Bretagne's Mechanical Science department research professors working in the IRDL lab have developed high-speed characterization techniques for fatigue properties in materials, assemblies and structures. These techniques have been validated by multiscale experimentation and allow manufacturing partners to predict and efficiently verify the lifespan of mechanical systems.

Continuous innovation

ENSTA Bretagne contributes to numerous innovative projects such as FASTLITE. Financed by the French Environment and Energy Management Agency's Investments for the Future program, this project focuses on the use of lighter materials in the automotive industry. ENSTA Bretagne contributed to the characterization and modeling of assembly strength.

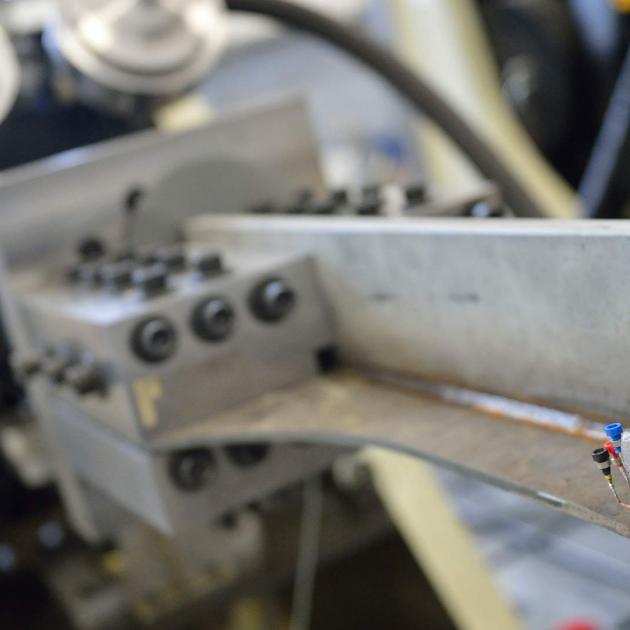

Extensive experimental facilities

The ENSTA Bretagne campus comprises 1,200 m2 of experimental facilities where various types of materials, structures and assemblies can be characterized on a wide range of scales. The MASMECA technology platform is constantly growing.

- Découvrir la spécialité "Modélisation avancée des matériaux et structures"

- Admissions :

- après CPGE (math sup/math spé) : admission sur concours Mines-Télécom. Formation en 3 ans ou 4 ans pour les IETA.

- après L3 : admission sur titre, dossier et oral. Formation en 3 ans.

- après M1 ou M2 : admission sur titre, dossier et oral. Formation en 2 ans.

Cette spécialité est offerte aux élèves Polytechniciens dans le cadre de leur 4e année.

- Découvrir ce parcours en Modélisation avancée des matériaux et structures

- Découvrir le Master international en Ingénierie automobile

- Admissions :

- admission sur dossier après L3 : Formation en 2 ans.

Le Master "Ingénierie de conception", parcours "Mécanique, matériaux et génie civil" est délivré par l’ENSTA Bretagne, l'UBO (Université de Bretagne Occidentale), l'ENIB, l’UBS (Université de Bretagne Sud) et l'INSA Rennes.

- En savoir plus sur ce master

- Inscription : UBS

- Contact ENSTA Bretagne : Sylvain Calloch

- Inscription à l’ENSTA Bretagne, rattachement à l’école doctorale SPIN et au laboratoire IRDL

Les recherches sur les matériaux et structures sont au cœur du projet scientifique de l’IRDL, qui réunit le CNRS et les équipes de sciences mécaniques de 4 campus bretons. Des entreprises industrielles de toute la France et de nombreux domaines d’activités s’appuient sur les compétences et connaissances du laboratoire et de l’ENSTA Bretagne pour mener à bien leurs projets de R&D.

Exemples de projets de recherche :

Composée de 5 plateaux techniques, MASMECA concentre de nombreux moyens d’essais en caractérisation dynamique, thermo-mécanique et physico-chimique.