Research areas

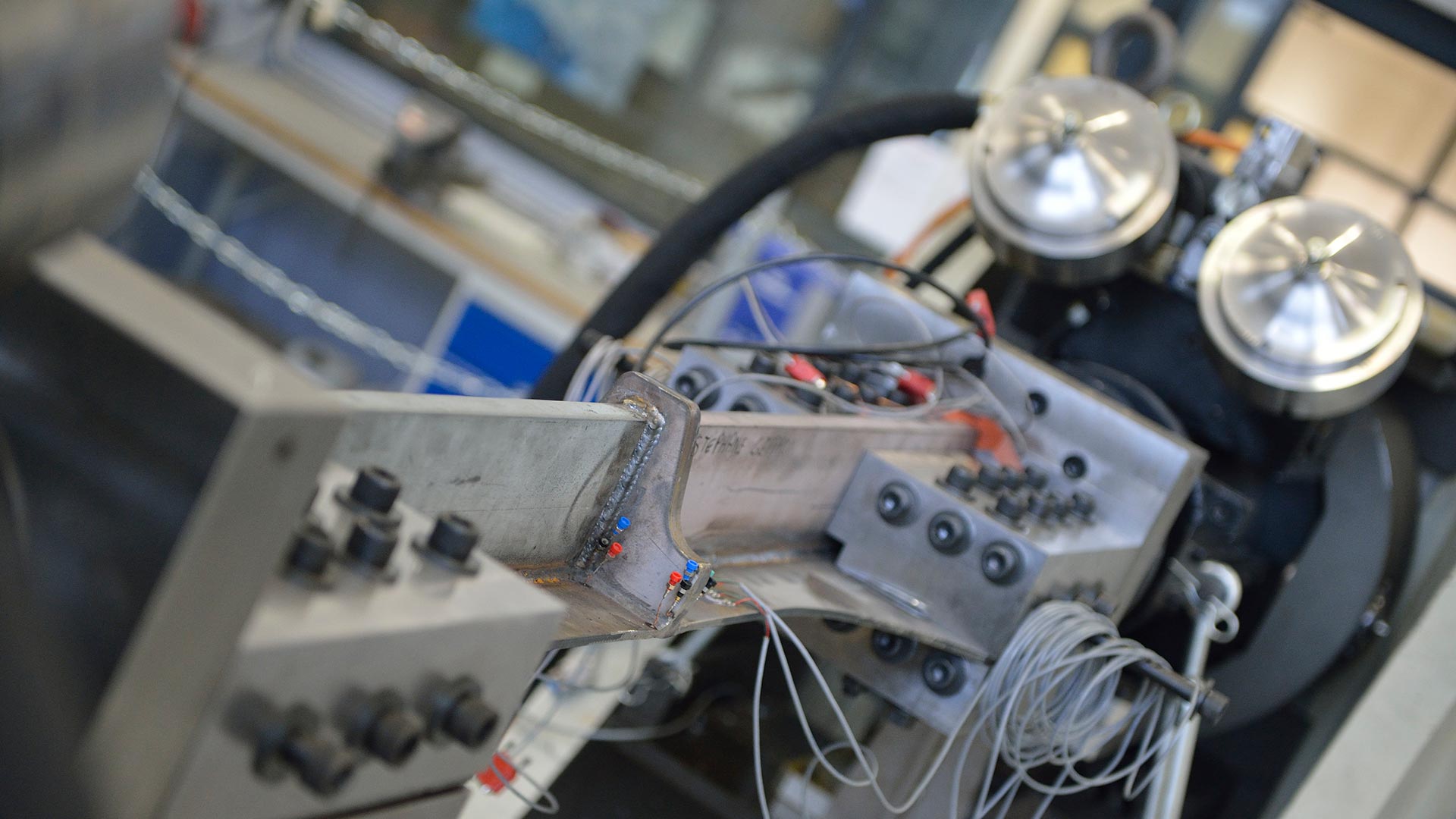

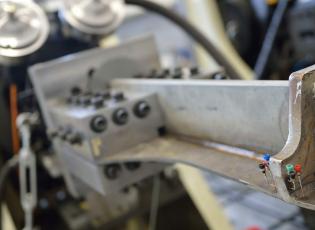

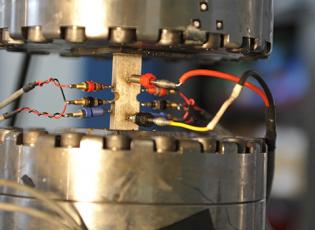

- Fatigue and self-heating of materials and structures (metals, composites and organic materials).

- Behavior and fatigue of active materials (piezoelectric or shape memory materials).

- Thermal and marine aging of organic materials.

- Non-linear behavior of heterogeneous materials.

This applied research, while addressing fundamental scientific questions, is conducted with European manufacturers from a broad range of sectors, particularly automotive, aeronautics, energy and materials suppliers.

Expertise

- Theoretical approach: behavior laws, modeling of irreversible processes and multiscale modeling.

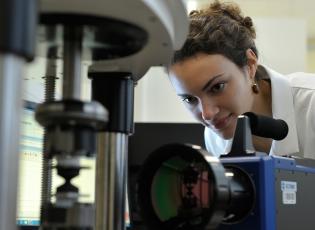

- Experimental approach: a test for every scale; field measurements for rapid characterization; developing new tests.

- Numerical approach: implementation of behavior laws, numerical multiscale approaches, design and diagnostic tools.

Keywords:

Fatigue, aging, fatigue resistance, modeling, tests.

Led by ENSTA Bretagne (Institut de Recherche Dupuy de Lôme1) with Naval Group and Safran, including the P’2 Institute, the “Self-Heating” chair has been accepted by the Agence Nationale de la Recherche (ANR) (National Research Agency). For four years, the teams will work on the heat signatures of materials. The aim: predict their in service performance and fatigue life.

- Total budget : 2 050 000€ financed by the ANR and the Safran and Naval Group industrial groups

- Period : 4 years. It will begin officially on 1 December 2020.

- Dedicated team : 8 PhDs, 4 post-doctorates and 13 research supervisors

- Title : Characterization, modeling and rapid prediction of the polycyclic fatigue properties of materials based on thermometric measurements

- Objective : The rapid prediction and determination of the polycyclic fatigue properties of materials based on the study and modeling of the heat signature of damage mechanisms.

This research program is based on the “self-heating” method, that is to say, measuring the temperature of a material in precise experimental conditions. This technique enables the prediction of weak points, which can then be factored into design office calculation codes and thus delay or even avoid damage when designing a ship, submarine or plane. The Safran Group and Naval Group both wish to develop and extend this scientific “heat measurement” (or self-heating) approach to all the materials used in their respective applications, and are interested in the parameters at play in the fatigue of their materials (temperature, manufacturing process, type of load, surface preparation etc.).

Lire l'article complet sur le projet de recherche RESISTANCE portant sur la caractérisation des contraintes dans les composants structurels en acier de forte épaisseur.

Un projet mené en partenariat avec Naval group dans le cadre du laboratoire commun Gustave Zédé.

Fatigue of a marine thruster made by additive manufacturing.

This project carried out with IFREMER focuses on durable and flexible polyamide moorings for marine renewable energy applications.

Fatigue design thermomechanical research work for 3D-woven composite materials in aeronautical applications; rapid determination of the high cycle fatigue properties (based on self-heating testing under cyclic loadings) of metal alloys for turbojets.

The fatigue design thermomechanical research work focuses on parts made from different materials (polyurethane foam or glass fiber reinforced thermoplastics).