Research areas

- Study and optimize assembly processes, by assembling different types of material, treated with new surface preparations.

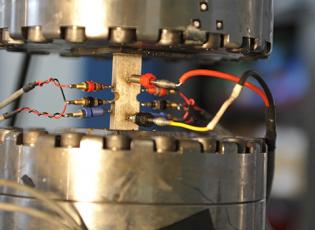

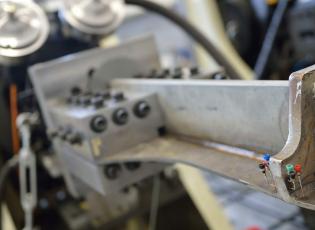

- Perform in-core instrumentation of assemblies (FGB, QRS, CIN, etc.) and use original experimental devices.

- Develop sizing tools for adhesively-bonded assemblies and factor in the parameters associated with the bonding processes.

- Characterize long-term strength of assemblies in harsh environments.

- Develop hybrid techniques (e.g. weld-bonding) for multi-material structures, to achieve high performance in terms of mechanical characteristics.

Expertise

- Assembly instrumentation

- Characterizing the multi-physical properties of materials and the long-term behavior of bonded and welded assemblies

- Multiscale modeling of physical phenomena during and after assembly, until failure

Keywords

Assembly, Bonding, Welding, Sintering, 3D printing, multi-material

Mechanical modeling, a performance prediction tool for assembling innovative structures by bonding

Bonding is gaining ground across the industrial spectrum for its many advantages in terms of streamlining, combining different types of materials or assembling small structures. These assemblies need to be optimized via modeling to achieve precise performances and lower the carbon footprint of certain activities, comply with new standards or branch out into new markets (new materials, new energy sources, etc.).

With that in mind, manufacturers are calling on researchers at the IRDL laboratory’s “multi-material assemblies” research hub, who particularly study the long-term strength of the adhesive and multi-material structure sought, come up with innovations in assembly processes and develop hybrid techniques.

“In the laboratory, we reproduce the industrial assembly process to be studied and perform tests under variable mechanical loading to develop models for predicting how the structure will behave depending on the stress it is being put under,” explains David Thévenet.

Development of a multi-material bonded structural assembly providing ballistic protection (2018-2021; in collaboration with the PTR3).

Thermal and mechanical characterization of aluminum/steel multi-material assemblies for vehicles (Funded by Bpifrance and Stellantis)

Characterization and modeling of the behavior of thick bonded interfaces (funded by Institut Carnot ARTS, the Brittany Region and Finistère Département)

The high-elongation adhesives used as thick applied seals are currently used to serve a structural assembly purpose (e.g.: ship hull, wind turbine blade, etc.).

This requires the implementation of suitable sizing methods that can factor in the behavioral complexity of such systems. Original tools have thus been developed in the context of the collaborative project COCOA (Brittany Region/Carnot Arts) involving the LAMIH (joint research unit/UMR CNRS 8201) and CETIM. Modeling of the damage of the bonded interface is compared to the findings of cracking tests under complex loading.

Development of a technological test for validating the behavioral modeling of an adhesive subject to impact loads (funded by SAFRAN Composites - collaboration with PTR3)

Durability of bonded structural repairs (funded by AID)

Analytical and digital modeling of the lateral buckling of offshore pipelines (Funded by the Brittany Region)

13 areas of innovation have been determined for this European project that brings together 37 partners from 11 countries.

The team leads the work carried out on the durability of bonds between a composite module and a metal structure and on the setting up of a high cycle fatigue design calculation chain for steel thrusters made using additive manufacturing, with large-scale validation testing (2017-2020 with PTR 2 and 5).