The PIM team – Multiscale propagation and interactions

In particular, this research work focuses on “smartening up” the systems designed to acquire and use the observations provided by radar systems (airborne or satellite) or geolocation systems such as GPS.

Applications

Radar; electronic warfare; geolocation and navigation; marine pollution; monitoring, maritime safety and security; microwave remote sensing; target recognition (based on radar signals/images).

Topics and expertise

- Multiscale and multiphysics electromagnetic simulation and modeling

- Wave propagation and interaction with the environment (sea, atmosphere, land).

- Microwave frequency system modeling and simulation (link budget, microwave remote sensing, experimentation, etc.).

Purpose: studying and developing innovative technological building blocks for safer and more efficient navigation for commercial vessels.

- Partners: ENSTA Bretagne/Lab-STICC, SAFRAN, Diades Marine, ENSM

- Funding partner: ADEME (“Ships of the future” roadmap, Investments for the Future program).

This project focuses on signature estimation for complex naval targets at sea (use of Gaussian beam summation and tracing).

- Funding partner: The French Government defense procurement and technology agency (DGA).

CEPAMOCS project focuses on parameter characterization and extraction from a heterogeneous sea surface observed by various satellite sensors.

- Funding partner: DGA.

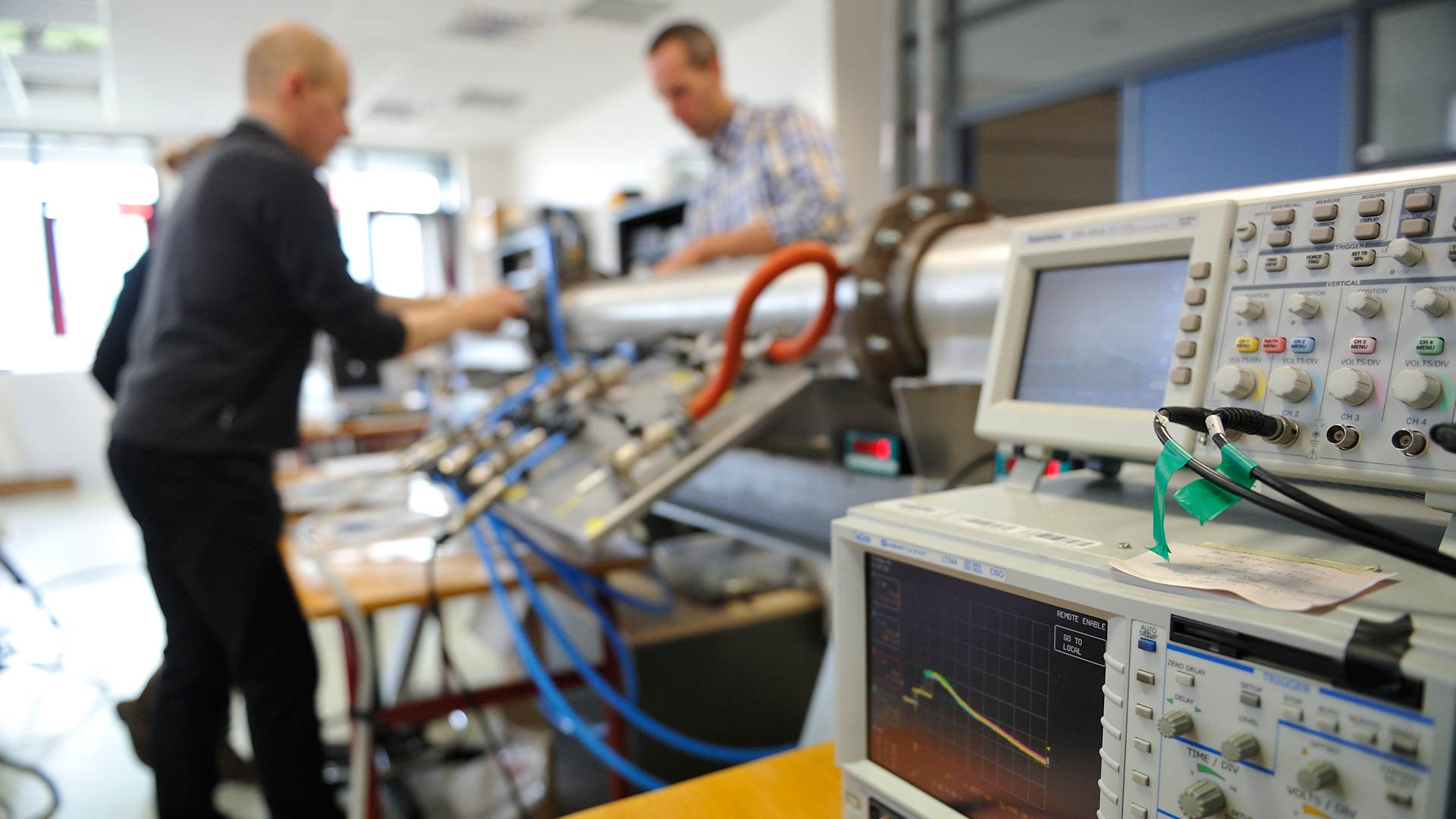

ENSTA Bretagne has purchased new equipment for the SYMOC project (CPER1 SOPHIE: ICST & waves, and photonics). This equipment consists of:

- UP/DOWN converter modules for frequency translation of the transmitted and received signals;

- Broadband antennas to cover the full range of frequencies used.

contact

The MOCS team – Methods and tools for circuit and system design

The team works on methodologies based on the association of heterogeneous models, as well as on scalable model checking: proving the systems’ correctness by construction.

The team also works on the securing of the compilation flow for reconfigurable circuits and on the virtualization of reconfigurable architectures to design durable and secure systems on chip (SoC).

Expertise:

- Modeling and simulation techniques

- Programming languages and their semantics

- Formal verification techniques

- Reconfigurable hardware virtualization and programming techniques

- Computer security and cyberdefense

Associating executable models for the operational simulation of defense systems. In collaboration with Sodius.

Execution and formal verification of the models of systems developed using the NATO Architecture Framework (NAF). In collaboration with PragmaDev.

Securing overlay architectures for digital circuits to remain operational for long periods of time (school study).

contact

The COM team – Digital communication

Applications

- Medicine

- Smart farming

- Internet of Things

- Electronic warfare

- Robotics

- Telecommunications, beamforming

Expertise

- Blind signal processing methods

- Spectrum sensing

- Cognitive radio

- Game theory

- Wireless transmission

- Acquisition and processing of the electrocardiograms of a fetus and its mother using wireless sensors.

- Characterization and classification of deep vein thrombosis (blood clot, Figure 1).

- Using EEG (electroencephalography) and EMG (electromyography) signals for wheelchair control by a paraplegic individual.

- Limb volume measurement using a 3D camera.

- Making a wireless ECG sensor.

- Building a simulator for the faculty of medicine.

- 3D vein mapping.

contact

The PRASYS team – Perception, Robotics and Autonomous Systems

Such systems are based on three pillars: perception, action and the interaction between the two. Any autonomous perception system must be able to simultaneously analyze the data collected in relation to its immediate environment, become familiar with this environment and, depending on what this environment is, autonomously organize the steering and navigational aspects of its mission. This recent issue stems from the field of robotics in which the robot-environment interaction occurs via the sensor, which requires a study of the action-perception mechanisms.

Two main areas of focus have thus been defined: perception and action. Interaction between these two areas of focus is then essential for the system to be autonomous.

- Research focus 1: Autonomous action

- Research focus 2: Autonomous perception

Perception (research focus 2) is the process by which the system attempts to understand its observations and devise a relevant representation, not only of the environment’s current state, but also of its uncertainty. Using the perception’s results, the system must then reason out the actions (research focus 1) it must implement to achieve its mission goals, according to certain criteria such as efficiency, safety, speed, and energy consumption.

APPLICATIONS

Defense and security, underwater archaeology, harsh environment operations

EXPERTISE

The team comprises researchers with expertise in information processing, robotics and automation. The team provides new mathematical tools, including set theory methods, suitable for managing uncertainties in unstructured environments such as the marine environment.

“NAVIDRO” is a 12-month research contract for the development of an AUV precise navigation simulator.

36-month project for the validation of autonomous drones and drone swarms carried out with Ecole Polytechnique, ISAE and ENSTA ParisTech.

A 24-month study on the generation of computer-generated sonar images and on the automatic detection and classification of targets using deep-learning techniques.

24 months with OXXIUS, Thales and IMTA: lasers, net detection and avoidance, underwater communication.

Ident3D (36 months): A study on 3D data processing for mine identification.

contact

The TOMS team – Processing, observations and statistical methods

Development of signal assessment, detection and representation methods. Marine and underwater environment monitoring: acoustic source localization, environmental characterization, the nature and evolution of the seabed, object detection and recognition.

Space and airborne remote sensing: space-time estimation of geophysical fields and ecological dynamics; object detection and recognition (ships, planes, etc.); monitoring of areas of interest (detection, observation, etc.).

Expertise:

- Marine biology.

- Passive acoustics, synthetic aperture radar.

- Advanced signal/image processing: antenna processing, time-frequency analysis, nonlinear methods, Bayesian inference, parsimonious models, compressed sensing.

- Data science for the sea and big data: machine learning (deep learning, etc.).

Applications :

Defense (underwater acoustics and radar), marine biology, environment monitoring.

Deep learning for multiple target detection and recognition in variable background. (Partners: IRISA, UBO UMR AMURE, MBDA)

Assessment of the ecological and socio-economic consequences of killer whales and sperm whales depredation on French longline fisheries: implementing a techno-economic approach for its suppression. The team uses passive acoustic monitoring to assess the impact of the noise coming from ships on cetacean attraction. (Partners: CEBC-CNRS, MNHN, UBO AMURE, INRA BIOSP, IRD MARBEC, IFREMER)

Hydroacoustic observatory of seismicity and biodiversity in the Indian Ocean (Partner: LGO UBO).

Whale monitoring using an acoustic glider (Partner: Total Foundation for Biodiversity).

(Open Science meets Ocean Sounds Explorer): a collaborative underwater passive acoustics project for ocean observation (Partners: IMT Atlantique, IUEM, WHOI [The Woods Hole Oceanographic Institution]).

For the characterization of marine environmental fluctuations (DGA TN order; in collaboration with WHOI).

contact

Gustave Zédé joint laboratory

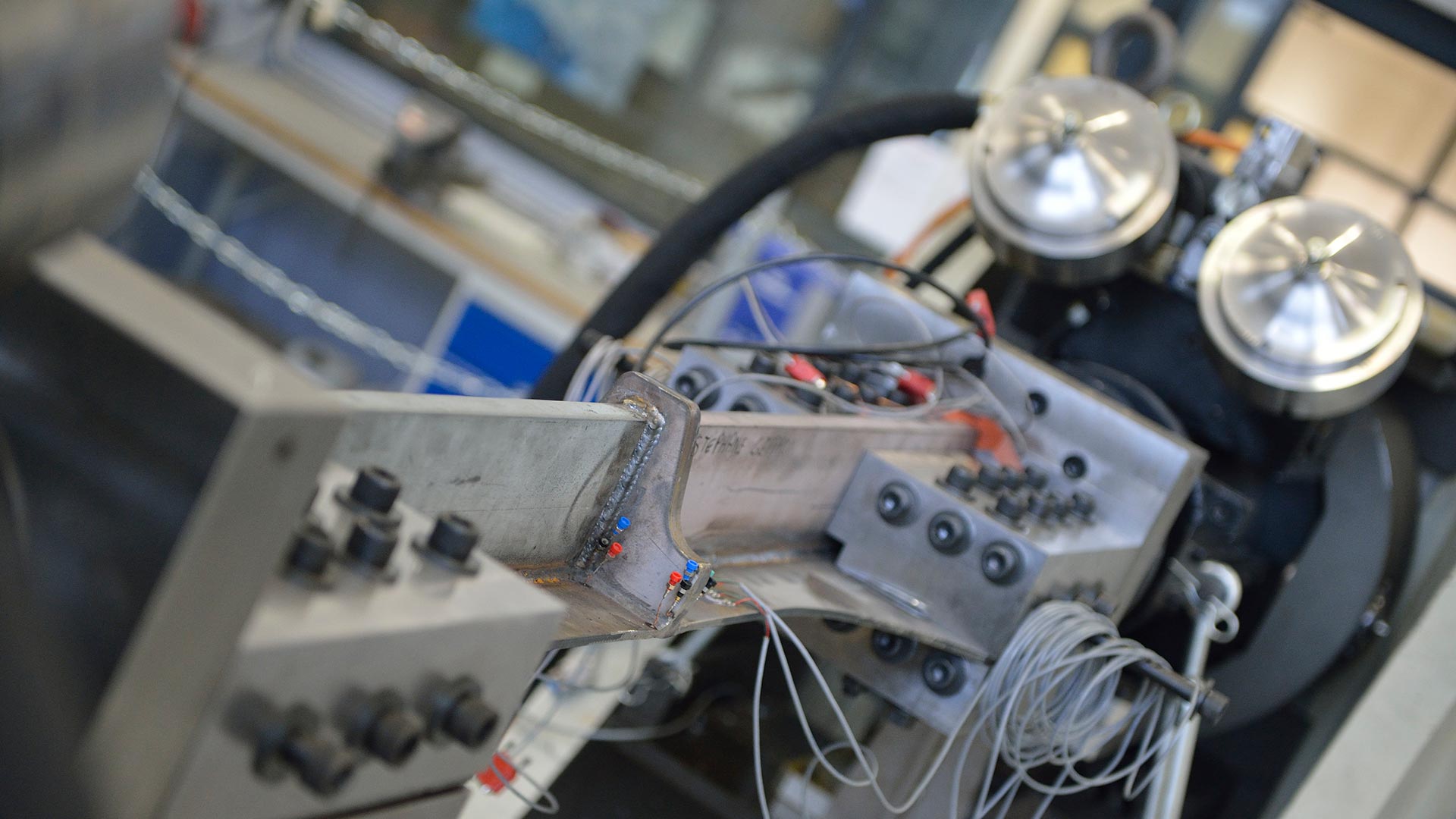

The research work conducted at the Gustave Zédé joint laboratory has 3 main areas of focus:

- The rapid characterization of the fatigue properties of materials

- The rapid characterization of the fatigue properties of assemblies

- New manufacturing processes and fatigue behavior

This project brings together 37 partners from 11 countries to focus on 13 areas of innovation. The team leads the work carried out on the durability of bonds between a composite module and a metal structure and on the setting up of a high cycle fatigue design calculation chain for steel thrusters made using additive manufacturing, with large-scale validation testing (2017-2020 with PTR 2 and 5).

Fatigue properties of as-welded and post-weld treated assemblies (2018-2020, CIFRE PhD thesis).

Improving design methods for the production and industrialization of submarine hulls. The project will focus on two major topics: forming and fatigue behavior. The goal is to better define the initial mechanical state of the formed structure so as to take better account of its impact on the structure’s in-service behavior. (2019-2022)

Il porte sur la fatigue multiaxiale des arbres d’hélice.

Dans le cadre d’une thèse, les travaux visent la caractérisation rapide des propriétés en fatigue des matériaux métalliques utilisés.

contact

Experimental facilities

Every year our research facilities make significant advances and allow researchers to meet strategic challenges in the fields of ship design, cyberdefense, marine observation, etc.

Housed in a 2,000m2 research space, the MASMECA technology platform is equipped to perform multi-scale characterization of all types of materials, assemblies and structures. It works in partnership with the IRDL lab and Naval Group's Gustave Zédé lab.

- Dynamic characterization (high loading-speed testing)

- Thermomechanic characterization (controlled-environment mechanical condition testing)

- Physico-chemical characterization (evaluating the effects of microstructure on materials’ mechanical behavior)

- Measurements and observations

- Prototyping

The ECO-SYS-MER project, led by IRDL (ENSTA Bretagne, UBS, UBO, ENIB and CNRS) and funded by CPER 2015–2020, aims to improve and test the reliability of mechanical systems in the marine environment, working on a scale ranging from materials to systems.

The project has received €3,130K of new equipment and experimental facilities, with €2,075K of this amount invested at ENSTA Bretagne.

Recent acquisitions:

- Scanning electron microscope

- X-ray diffractometer and equipment associated with this observation method

- Kite sail piloting system

- TriboIndenter

- Internal pressure loading system for traction/compression loading machine

- Liquid nitrogen dispensing system

- Potentiostat for corrosion testing

- Fluid flow tracking device for high-speed camera

- Command system for actuator test bench

- etc...

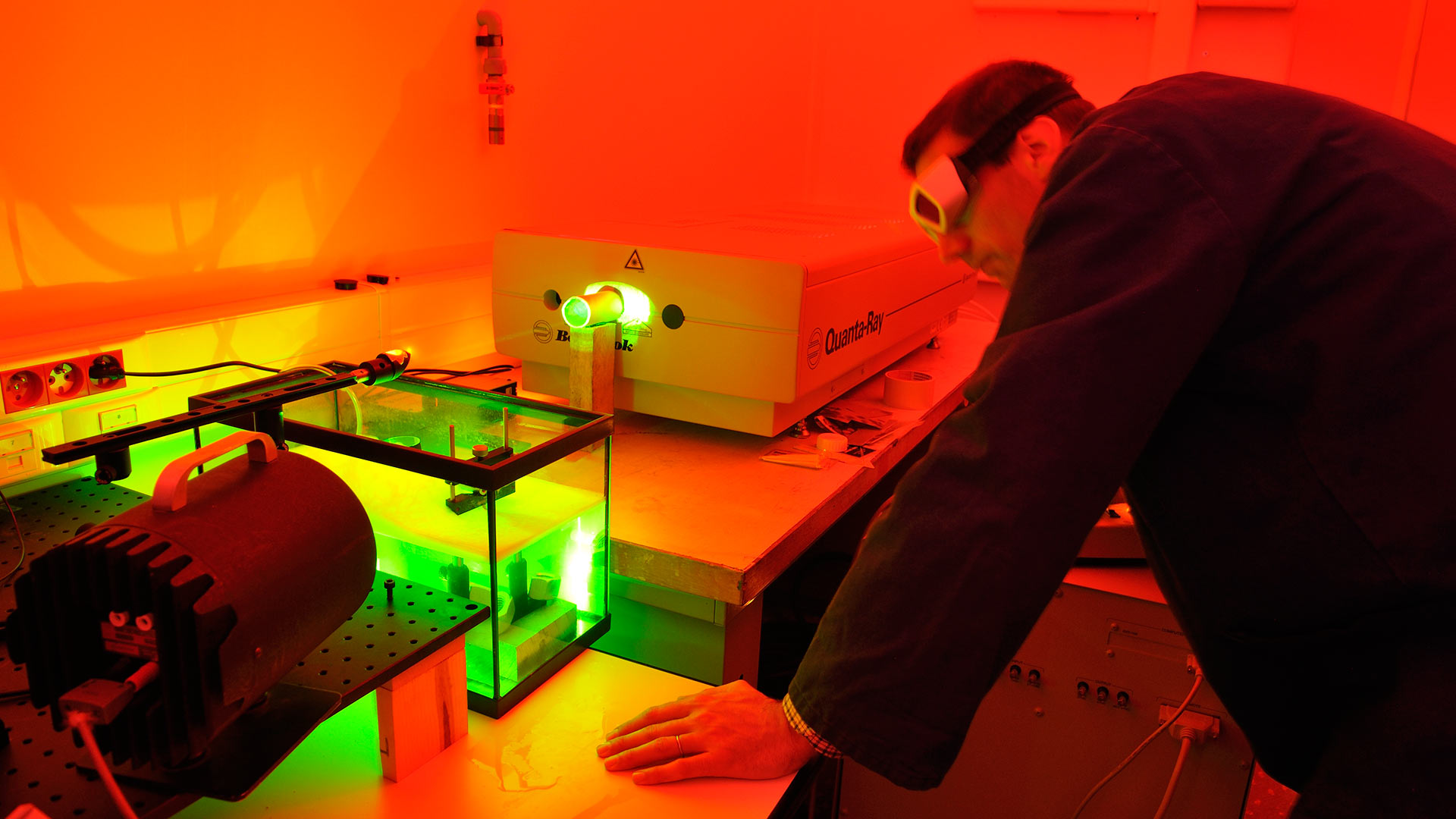

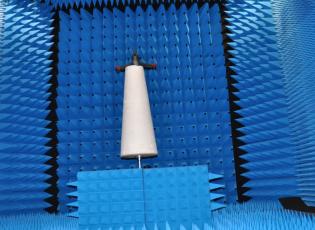

ENSTA Bretagne has extensive on-campus experimental facilities dedicated to ICST, including:

- Anechoic chamber

- Software Defined Radio platform

- Drone systems and robotics area

- Test tank

- Hydrographic vehicles

- Robotics area

As a member of Brittany's Pôle d'Excellence Cyber, ENSTA Bretagne carries out research in fields ranging from antennas and analog channels to threat analysis through formal risk assessment.

The school has benefited from €2M of CPER-funded acquisitions and, in the context of the Cyber SSI Project, has already acquired a calculator, a supervisory control and data acquisition system (SCADA) and a radio frequency bench.

Autonomous underwater robots have proven their ability to consistently make high-quality and Sprecise measurements and observations in marine environments.

This project aims to expand their potential by replacing a single large autonomous underwater robot with a swarm of multi-environment robots (air, land and underwater).

CPER has approved an €865K budget for the purchase of components to assemble this robot flotilla, allowing ENSTA Bretagne to acquire surface drones, autonomous underwater microrobots, acoustic sensors, a mobile command center, small air drones, etc.

This project aims to develop a high-frequency data acquisition system able to characterize the marine environment under various conditions.

Additional equipment for building this system, including up/down converters and broadband antennas, have been added to existing experimental equipment.

The goal of the I-ROMI project is to create a research and experimentation platform to optimize marine observation systems, aiming for higher-quality measurements; less costly, more robust and adaptable observatories; less intrusive observation structures and protocols; and more user interaction.

In particular, the project will study the development of innovative and efficient passive acoustic observatories to monitor underwater ambient noise produced by geology, fauna and human activity.

Recent acquisitions include portable hydrophones and a calculation server.

Pyrotechnic impacts

Anticipating and limiting the effects of explosions and underwater activities