For several decades, underwater wings, known as hydrofoils, have flourished under the hulls of sailboards and sailing boats. Comprising a horizontal part, connected to the hull by a vertical arm, their operation is similar to that of an aircraft's wing. When the boat's speed is high enough, the horizontal part of the hydrofoil lifts the boat's hull out of the water. The friction between the boat and the water is thus reduced and the boat increases speed. This speed is currently sought after for competition sailing boats. However, this is not the airfoil's sole application. Research is under way to reduce the electrical and fuel consumption of future motorboats.

Development of complex models

Improving the performance of hydrofoils is therefore a challenge for the future. This is why a team of researchers in mechanics and hydrodynamics from ENSTA Bretagne (IRDL laboratory ), in partnership with IFREMER and IRENav, launched the OptiFoil project in 2020.

"Ideally, the idea is to develop numerical models capable of assessing the performance of any type of hydrofoil", said Matthieu Sacher, a lecturer at ENSTA Bretagne and a specialist in fluid/structure interactions.

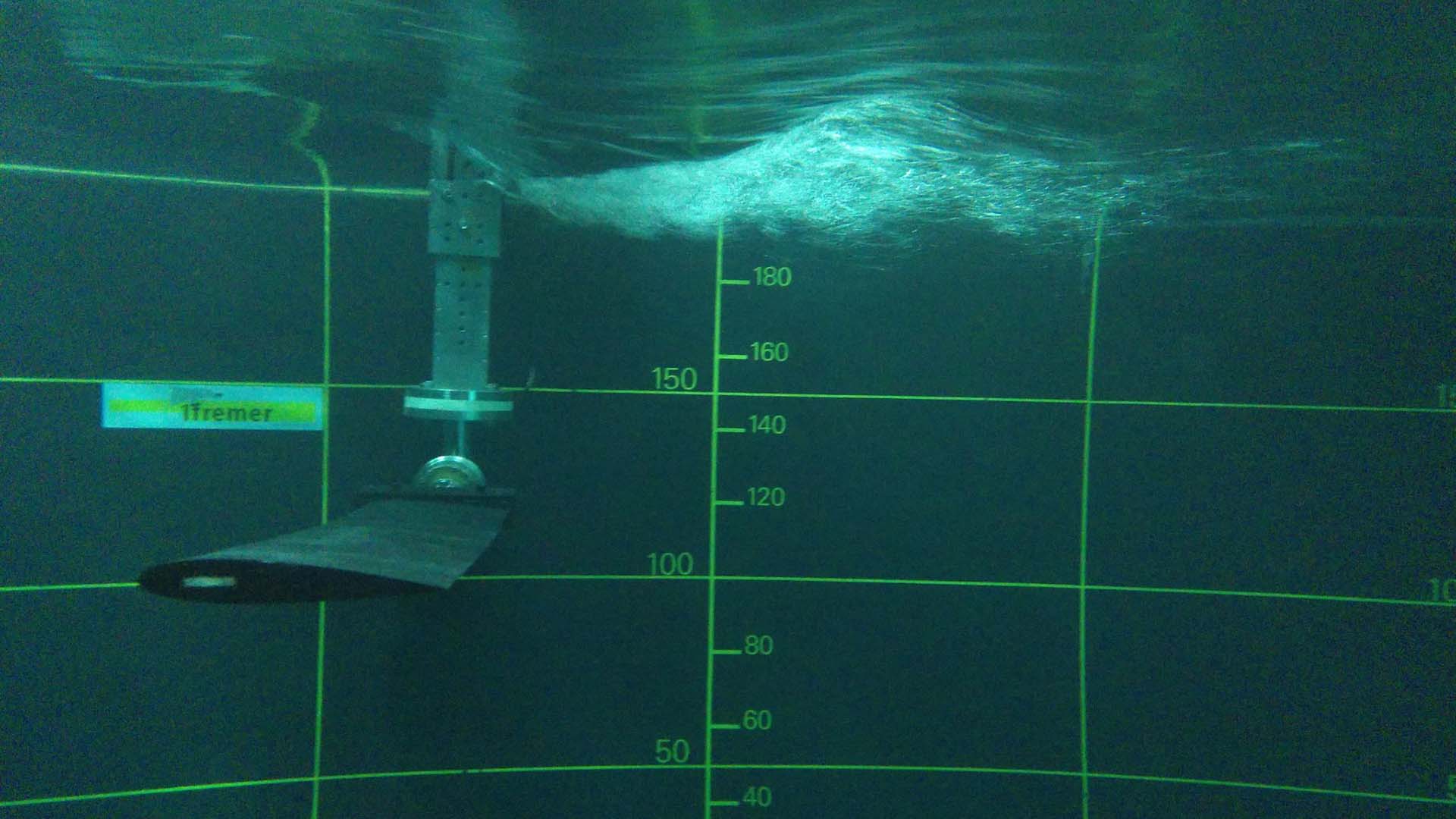

The modeling of certain physical phenomena, such as ventilation or cavitation which can occur when the hydrofoil operates close to the air/water interface, or the non-linear response of the hydrofoil's structure under hydrodynamic loading, is a real scientific challenge. These phenomena can affect the hydrofoil's efficiency. The challenge is to limit their effects!

Confirmation of the models in tank tests

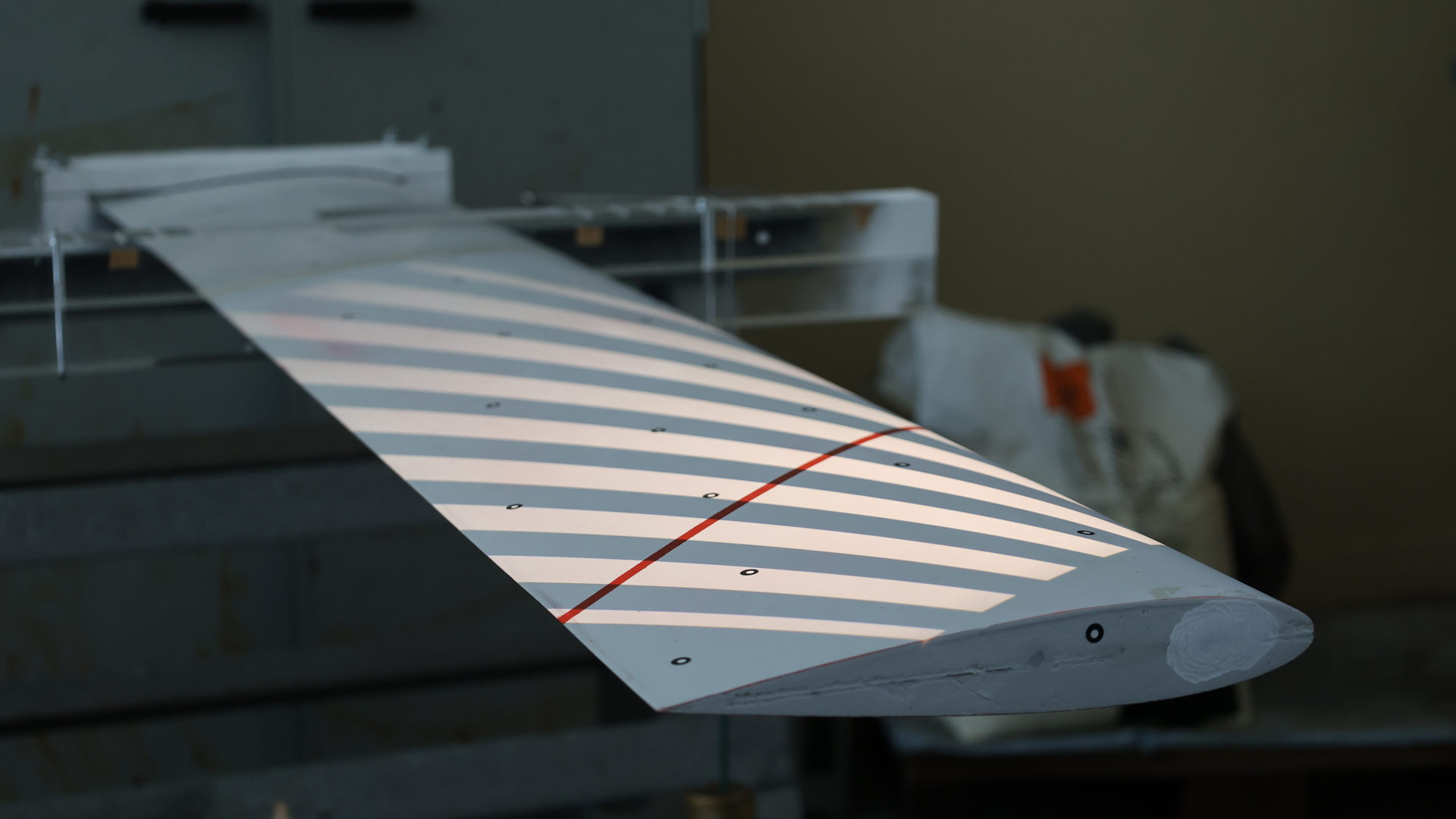

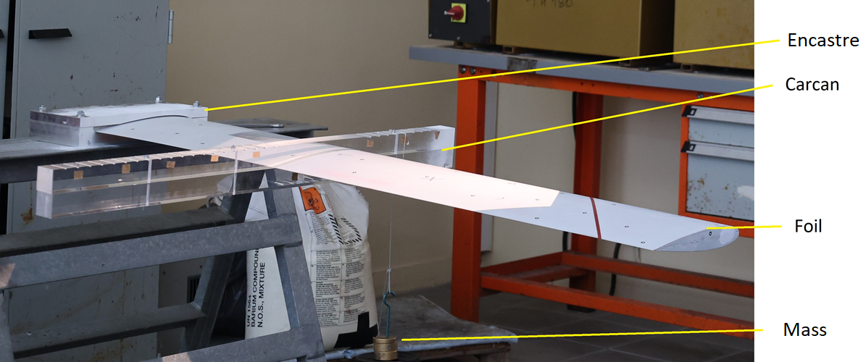

For this purpose, the OptiFoil project's scientists decided to first test the hydrofoil's performance based on the mechanical properties of its structure. In a water circulation tank at IFREMER in Boulogne-sur-Mer , they studied the hydrofoil's structural response when subjected to a flow. The design of the fibers that make up its structure can indeed affect its performance. "As the hydrofoil moves through the water, the hydrodynamic forces displace and deform its structure. Bending/twisting couplings can occur and change the machine's speed". The vertical component of this hydrodynamic force is the lift, which raises the hydrofoil and therefore the boat, and the horizontal component is the drag .

"The experimental results are being analyzed. They will allow us to refine our models". In a second phase, the hydrofoil's geometry will be tested.

With the OptiFoil project, scientists will be able to propose models for assessing hydrofoil performance. "For now, we have focused on stationary case studies. We hope to continue these developments in a future project, including dynamic cases : swell, transitional phases (tacking, trim changes, etc.) or dynamic responses to external disturbances.”

To carry out this research, the OptiFoil project researchers have set up a dedicated team that includes PhD students and post-doctoral research engineers, as well as ENSTA Bretagne engineering students and Ecole-Navale Master Of Science in research students. The OptiFoil project is funded by the Carnot ARTS and MERS institutes.

¹ IRDL : Dupuy de Lôme Research Institute

² Located in Pas-de-Calais.

³ Generally made of composite materials.

⁴ Which opposes the boat's forward speed