The Self-heating industrial chair is co-funded by the French National Research Agency (50%) and the industrial partners (50%), for a total budget of €2.05m over 4 years.

To date and to our knowledge, there is no other equivalent research program at global level bearing on the rapid characterization of fatigue properties of materials on the basis of thermometric measurements.

The Chair’s objectives

An academic and industrial partnership

The “Self-heating” ANR industrial chair brings together industrial (Naval Group, Safran Aircraft Engines, Safran Landing Systems, Safran Composite) and academic (IRDL – ENSTA Bretagne and the Pprime Institute) interests.

- This type of partnership gives the partner companies an opportunity to conduct research on an ambitious scientific theme with a direct bearing on some of their strategic key issues – in this instance the improvement of methods for characterizing materials and sizing structures with respect to fatigue.

- For ENSTA Bretagne and the Pprime Institute (P’), this type of partnership paves the way for considerable synergy on one of their main scientific themes and for participation in projects with high socio-technological stakes.

Dialogue between industry and academia is encouraged. Indeed, Safran and Naval Group are intending to co-opt the tools developed during the research, which is exploring a wide range of materials (metals and composites) in their respective areas of application: aeronautics and the naval sector.

Shorter test durations

In the high- and very high-cycle fatigue ranges, there is a notable need to develop methods for the rapid characterization of material properties. With that in mind, over the past few years ENSTA Bretagne has been developing strategies combining experimental approaches with mathematical modeling aimed at reducing test duration by a factor of 100.

Research-led training

A large number of staff from ENSTA Bretagne are involved in the “Self-heating” industrial chair project. With a view to strengthening the team, ENSTA Bretagne set a recruitment drive in motion for working on the subject: 8 PhD students and 4 post-doctoral students have joined the IRDL laboratory.

One of ENSTA Bretagne’s main goals is to train young doctors and post-doctoral researchers with consideration given to transfer of research results towards industry.

In all, some thirty staff members are involved in this project at ENSTA Bretagne (professors, PhD students and post-doctoral students combined).

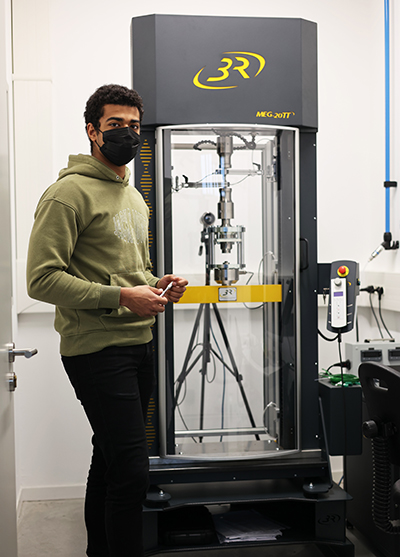

News: a new machine acquired for conducting research and for achieving the very high cycle fatigue range

In early November, ENSTA Bretagne acquired a very high frequency (20kHz) gigacycle fatigue machine. It is capable of running 10E10 cycles during 14 hours of tests, for example. This is a rare piece of test equipment, acquired in the context of the investments planned for the “Self-heating” ANR industrial chair.

The MEG-20TT machine is French-made. It can subject the test specimens to fully reversed (R=-1) cyclic loading or to tensile-tensile tests (0<R<1). The machine’s principle is based on ultrasonic guided wave excitation technology and has an embedded state-of-the-art very high frequency measuring and control electronic system.

Two of the "Self-heating" chair’s theses are dedicated to studying metallic material fatigue in the gigacycle range: at ambient temperature and at very high temperatures. The scientific challenge is to establish a link between the thermal response of materials subjected to cyclic loading and their life cycle in this fatigue range. This machine will meet the experimental requirements of both projects and enable development of the gigacycle fatigue theme at the laboratory.