Technological stakes : predict the in service performance of aircraft and naval systems

The ANR industrial chair in « SELF-HEATING » aims to answer a strategic and ambitious challenge laid down by Safran, Naval Group and the partner academic teams: predict in service performance and enable optimal sizing using the materials and assemblies which are best suited to each context and each part of the aircraft or naval systems architecture.

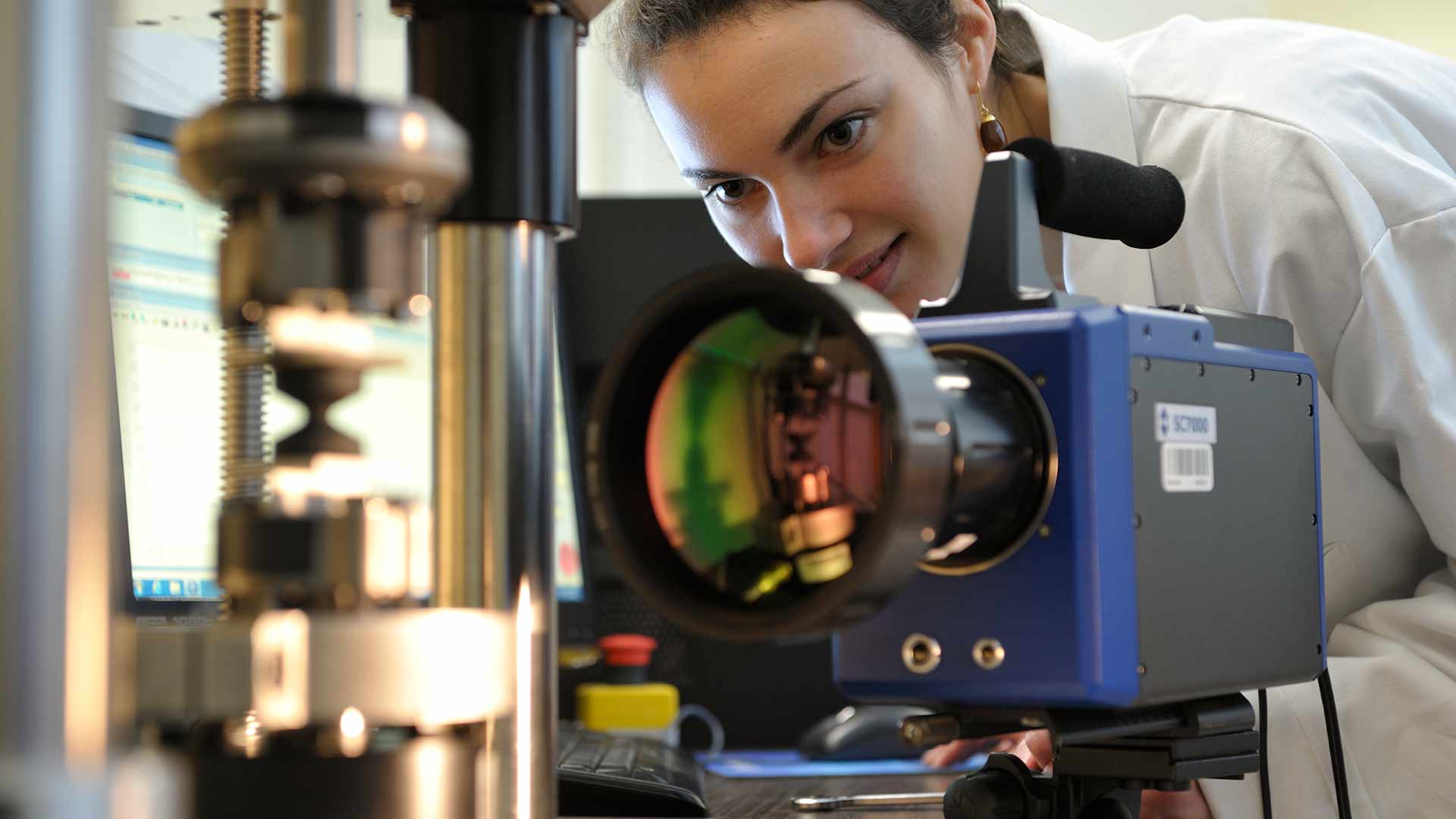

To do so, this research program is based on the “self-heating” method, that is to say, measuring the temperature of a material in precise experimental conditions. This technique enables the prediction of weak points, which can then be factored into design office calculation codes and thus delay or even avoid damage when designing a ship, submarine or plane. The Safran Group and Naval Group both wish to develop and extend this scientific “heat measurement” (or self-heating) approach to all the materials used in their respective applications, and are interested in the parameters at play in the fatigue of their materials (temperature, manufacturing process, type of load, surface preparation etc.).

« Self-heating » taking a material’s temperature

The Institut de Recherche Dupuy de Lôme (IRDL) research team, based on ENSTA Bretagne’s campus, works on the use of such heat measurements in predicting the fatigue life span of structures, that is to say their capacity to resist a relatively weak stress which repeats a large or very large number of times.

The scientific method of measuring and modeling self-heating is very promising. Over the last 15 years, it has given very good results in the rapid and accurate determination of the fatigue limit of materials. It offers many advantages for cutting edge companies and industries; fast characterization and prediction of material properties, precise information, specific experimental methods which are more sparing of materials and characterization test expenses which are 10 times lower.

It consists in measuring and modeling the heat signature of materials. The studies cover all categories of materials that are subject to possible damage due to high in service stress. Like several other research teams in the world and Europe, over several years, ENSTA Bretagne (via the Institut de Recherche Dupuy de Lôme), has been developing its know-how in this field alongside industrial groups such as Safran, Naval Group and other major names in French industry.

A chair which includes ENSTA Bretagne/IRDL Laboratory, Naval Group, Safran and lnstitut P’, the first of its kind in Brittany!

ENSTA Bretagne’s IRDL team, the two industrial groups, Safran and Naval Group, and the Institut P- presented the “Self-Heating” program to the ANR for the 2020 industrial chairs and was awarded its co-funding for summer 2020. The research budget is in the order of 2,05 million euros over 4 years and has enabled the constitution of a dedicated team (8 PhDs and 4 post-doctorates) and the acquisition of complementary test equipment. This is the first industrial chair of its kind on Breton soil.

characterization, modeling and rapid prediction of the polycyclic fatigue properties of materials based on thermometric measurements.

the « SELF-HEATING » project, financed by the ANR and the Safran and Naval Group industrial groups, will begin officially on 1 December 2020, for a period of 4 years.

The rapid prediction and determination of the polycyclic fatigue properties of materials based on the study and modeling of the heat signature of damage mechanisms.

Institut de Recherche Dupuy de Lôme (IRDL, UMR CNRS 6027, part of the Institut Carnot ARTS, including ENSTA Bretagne, UBS, UBO, ENIB) ; Institut P’ (UPR CNRS 3346, including the Université de Poitiers and ISAE-ENSMA)

Companies in the SAFRAN Group, Safran Aircraft Engines, Safran Landing Systems and Safran composites and the NAVAL GROUP

€ 2 050 000 over 4 years

Represents 8 PhDs and 4 post-doctorates

13 research supervisors involved :

9 researchers from ENSTA Bretagne who are part of the Institut de Recherche Dupuy de Lôme (Sylvain Calloch, Célia Caër, Nicolas Carrère, Younes Demmouche, Cédric Doudard, Vincent Le Saux, Bruno Levieil, Yann Marco and Sylvain Moyne) and 4 researchers from ISAE-ENSMA who are part of the Institut de Recherche P’.