Researchers and manufacturers are joining forces in a sweeping research and development program wholly dedicated to the rapid characterization of very-high-cycle fatigue properties of structures and materials, a major challenge for industry.

Led by mechanical science research teams at ENSTA Bretagne (Institut de Recherche Dupuy de Lôme2) in conjunction with Naval Group, Safran and the Pprime Institute (P’)3, the "Self-Heating" industrial chair delves into the characterization and modeling of materials’ fatigue properties on the basis of thermometric measurements (self-heating). A ground-breaking scientific method compared with many current conventional approaches.

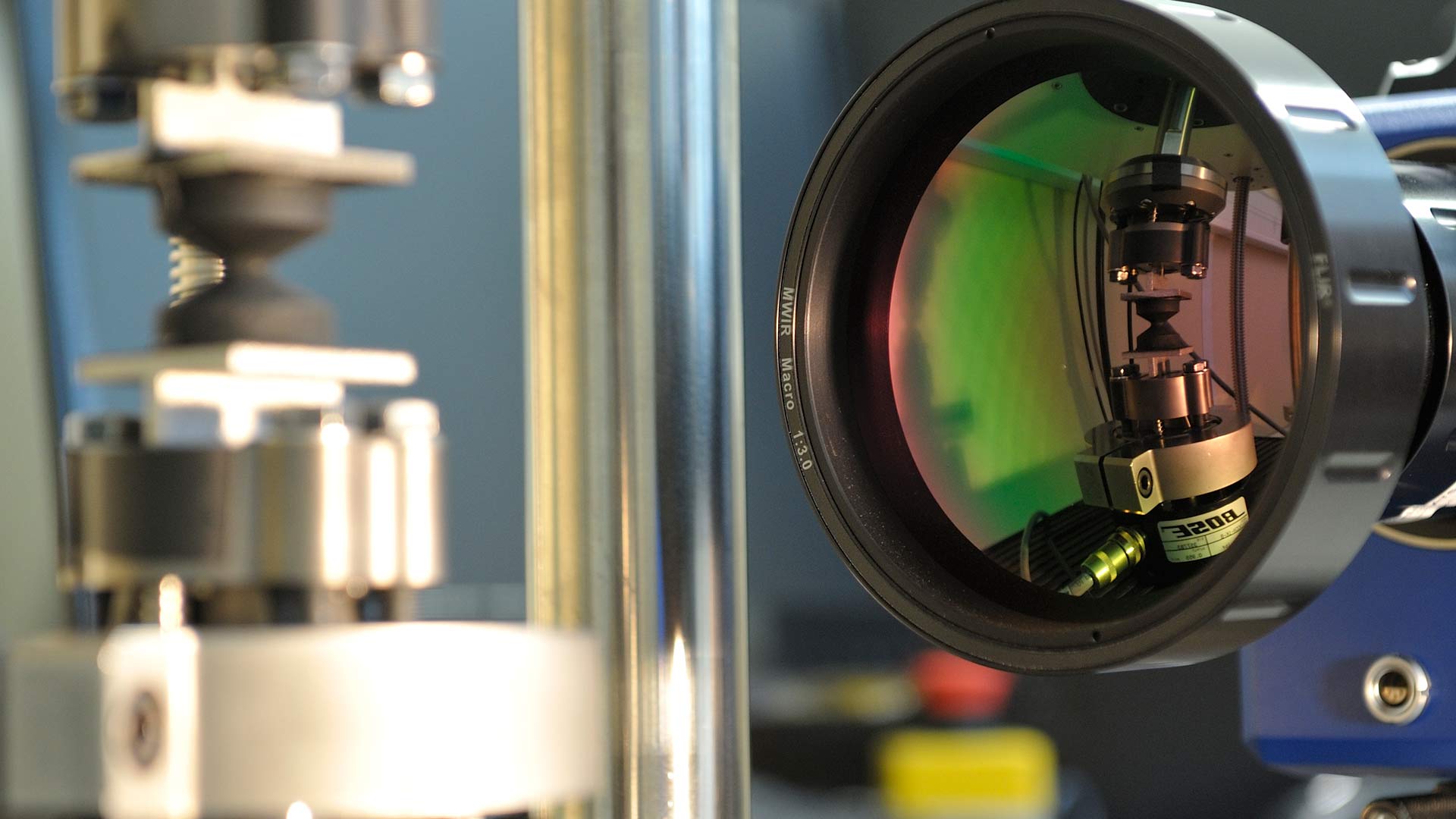

This study method combines modeling with experiments at different scales, at ENSTA Bretagne’s Brest-based test center. Given the associated savings in terms of time and cost, the consortium’s industrial companies immediately saw the benefits of getting involved in this project: reliable results available within the space of just a few weeks on the assessment of new materials’ and assemblies’ fatigue properties. This could ultimately speed up innovation in materials and assemblies, paving the way to new performances and gains in competitiveness alike.

The chair’s joint funding by the French National Research Agency (ANR) (50%) and industrial partners (50%) gives depth and breadth to the program which has just entered its 2nd year and achieved its objectives in terms of recruiting young researchers. Some fifty scientists and engineers have thus joined this ambitious program.

Predicting the in-service performance of aircraft and naval systems to prevent damage

The "Self-Heating" ANR industrial chair sets out to meet a strategic and ambitious challenge of Safran, Naval Group and the partner academic teams: predict in-service performance much faster than before and thereby enable optimal sizing using the new materials and assemblies best suited to each situation and to each part of the aircraft or naval system architecture.

To that end, this research program relies on the "self-heating" method, i.e. measuring the temperature of a material under precise experimental conditions. By reproducing the in-service stress endured by the material or part being studied, this technique enables the prediction of weak points, which can then be factored into design office calculation codes and thus delay or even avoid damage when designing a ship, submarine or plane. Both the Safran group and Naval Group would like not only to develop and extend this scientific “heat measurement” (or self-heating) approach to all the materials and assemblies used in their respective applications, but also to swiftly and significantly improve knowledge of the parameters at play in the fatigue of their materials (temperature, manufacturing process, type of load, surface preparation etc.).

An invaluable research methodology for industry which allows for faster design of materials that are best suited to the intended use, with the ability to characterize their damage phenomena and properties.

As highlighted by Sylvain Calloch, University Professor (ENSTA Bretagne, IRDL) and holder of the “Self-Heating” Chair

To date, there is no other equivalent research program at global level bearing on the rapid characterization of fatigue properties of materials on the basis of thermometric measurements. This is a tried and tested method by our laboratory which has acquired significant maturity in this field. The laboratory’s scientific knowledge, unprecedented experimental facilities and extensive experience working with industrial companies are renowned in France and abroad.

A partnership between academic and industrial partners aimed at meeting strategic challenges

The “Self-Heating” ANR industrial chair addresses common interests shared by industry (Naval Group, Safran Aircraft Engines, Safran Landing Systems, Safran Composite, Safran Tech) and academia (IRDL – ENSTA Bretagne and the Pprime Institute).

This type of joint venture gives the partners an opportunity to conduct research with a direct bearing on some of their strategic key issues – in this instance the improvement of methods for characterizing materials and sizing structures with respect to fatigue, whilst enabling ENSTA Bretagne, IRDL and the Pprime Institute to forge synergies on one of their main scientific themes and to participate in projects with high socio-technological stakes.

Dialog between industry and academia is encouraged. Indeed, Safran and Naval Group are intending to co-opt the tools developed during the research, which is exploring a wide range of materials (metals and composites) in their respective areas of application: aeronautics and the naval sector.

Julien Beaudet, fracture mechanics and fatigue expert at Naval Group, commends this partnership:

Naval Group’s participation in the "Self-Heating" ANR Chair builds on many years of research collaboration with ENSTA Bretagne, stepped up since 2015 at the Gustave Zédé joint laboratory. Understanding of material fatigue is of vital importance to industry in the constant quest to optimize ships’ maintenance in operational condition and maximize availability at sea. The self-heating method harbors significant advantages over traditional approaches. The aim now is to speed up the transfer of the method to industry, to extend it to other naval structures and materials and to standardize it thanks to the chair’s research findings.

Lionel Marcin, mechanical modeling expert at Safran:

Safran and the IRDL first worked together back in 2015 and have continued to strengthen their ties ever since. The ground-breaking characterization strategy outlined will help to drive forward the selection of viable material concepts (nickel-based super-alloys, additive manufacturing, composites in particular) and to control the fatigue properties of materials – a key issue for Safran. The SELF-HEATING industrial chair strikes us as a flagship project set up to succeed with a team bringing together the Safran group and Naval Group, IRDL and P’, which is highly complementary and motivated to press on with establishing a generic method for the rapid characterization of materials’ fatigue properties on the basis of thermometric measurements under cyclic loading.

Research-led training

Another of ENSTA Bretagne’s goals, the training of young researchers (PhD and post-doctoral students alike), is a key strand underpinning the program, which supports the transfer of knowledge towards industry.

Around fifty researchers (which includes research professors, PhD and post-doctoral students) are involved in the "Self-Heating" Chair, 8 PhD students and 4 post-doctoral students of whom joined the IRDL laboratory in 2021.

On the global stage, ENSTA Bretagne leads the way in terms of predicting the HCF properties of materials and structures through the study and modeling of dissipative phenomena under cyclic loading.

The “Self-Heating” industrial chair at a glance:

|

(1)The companies belonging to the SAFRAN Group involved: Safran Aircraft Engines, Safran Landing Systems, Safran composites and Safran Tech

(2) Institut de Recherche Dupuy de Lôme is a joint research unit (UMR no. 6027) of the French National Research Center (CNRS) which brings together mechanical science research teams from ENSTA Bretagne, UBS, UBO and ENIB.

(3) The Pprime Institute is an internal research unit (UPR) specializing in physics and engineering, bringing together Université de Poitiers, the CNRS and ISAE-ENSMA.